NOTHING IS IMPOSSIBLE WITH 3D PRINTING

In the beginning there is the product idea. Equipped with more or less concrete details, it will first be “put on paper.” In most cases, this task is performed by a design engineer or product designer.

The first draft is now followed by a litany of agreements and corresponding adjustments between the client and the executing agency. It can take weeks until the first prototype is ready…

Andreas Zeeh, designer at GETT, knows this tedious and sometimes nerve-racking scenario only too well. What revolutionized his work at GETT? The purchase of a 3D printer from Formlabs! He bundles how he works with it and the experiences he has gained in Part 2 of the GETTKNOWLOGY!

From dentures and tools to food – with the right 3D printer, the possibilities of producing three-dimensional objects seem unbounded. The GETT’s development unit has also participated in this technical achievement, as developer Carsten Thomas reports in his new blog post “Nothing is Impossible -3D Printing.”

Inspired by Jean Luc Piccard’s command to the replicator: “Computer! Tea! Earl Grey! Hot/” was printed right off the bat in resin.

Zeeh

Starting with a look back and a look forward

Ever since the start of industrialization, human beings have been trying to create things. However, the specifications have become increasingly complex and complicated during the course of time. This also applies to the machines and equipment needed for this purpose. Like everything in our lives, all these things are three-dimensional.

These kinds of ideas were picked up in the early science fiction movie world. The famous captain of the spaceship, Enterprise, Jean Luc Piccard, said to his replicator, for example, “Computer! Tea! Earl Grey. Hot.”. In response, the computer produced the drink that he wanted using the replicator. Of course, a great deal of water will still have to flow under the bridge until then, but you have to set goals…

How everything started …

The inventor of 3D printing was pursuing this goal in 1981. The American engineer, Charles W. Hull, invented 3D printing in that year by using stereolithography. However, it was 1988 before it was possible to buy the first 3D printer. Since that time, the number of available printers, materials and production processes has constantly increased. As a result, prices are now falling so much that 3D printing is increasingly finding its way even into private households. 3D printers are used for making models, for example, in private homes. People want to gain an impression of all that is possible when using the new technology. There is even a 3D printer called “Replicator” now. It may not be as powerful as its namesake in the movie, but how knows what the future might bring…

There are many different processes and even materials for making a 3D-printed part nowadays. The selection of material and therefore the production process is often defined by the conditions where the components are going to be used.

I would like to explain the materials and manufacturing procedures in greater detail in this blog post. However, I would like to focus on how we are using this new production process at GETT in this article.

Our initial experience …

We already had our first contact with the issue of 3D printing in 2012. The prices fell so sharply during that year that any investment quickly paid off. We therefore bought the 3DTouch Farb 3D Printer from BfB (Bits from Bytes). It had already been on the market for one year by this time and operated according to the Fused Deposition Modeling (FDM) principle. This involves melting a plastic strand (filament) and then adding one layer after another until the model that is wanted is complete.

We initially set ourselves the goal of manufacturing components for our own production purposes. The aim was to ease the pressure on our milling shop. We printed various aids used to manufacture our products with this in mind.

However, more than two years later, the manufacturer of our printer was taken over and the product support was halted. This meant that 3D printing took a back seat again at GETT for the time being…

The relaunch…

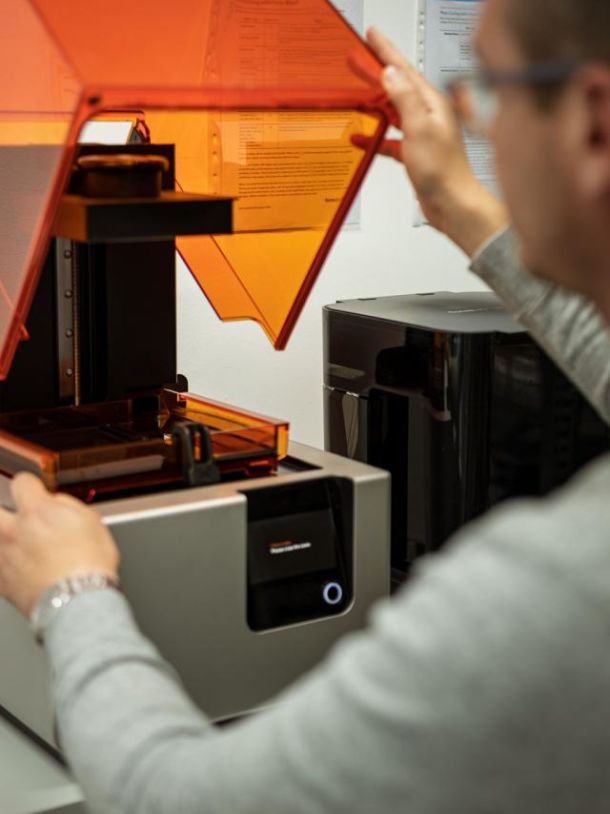

We once again started talking about purchasing a 3D printer in 2018, as the topic had increasingly come to the fore in industry. We conducted some market research and this resulted in us purchasing the Form2 from the Formlabs corporation.

This printer works according to the stereolithography principle. A laser cures a resin, layer by layer. In contrast to our first printer, this process prints top down. After this, any unhardened resin has to be removed from the components and curing finally takes place using infrared light. The material then obtains its physical properties.

The first printing results followed soon afterwards. We were all surprised by the high level of quality, but the “learning by doing” method applies here too.

We gradually learned to achieve even better results with the printer. We were able to make the first ancillary devices for our production work and achieved a very high degree of precision at the end. As a result, we plucked up the courage to make the first components for customized projects.

We were able to offer our customers a cheaper alternative to the normal injection molding process for the first time. As it takes too long to manufacture a component, we mainly use the 3D printer to make prototypes. You can then implement ideas, adapt them and optimize them for series production in a flexible and low-cost manner.

However, the system was not completely automated and we still had problems when postprocessing our printed parts. We solved these by buying the Form Wash and Form Cure units.

As the name suggests, Wash refers to washing. The excess resin is washed off the printed part. This takes place in a kind of washing machine. It works in line with the principle of ‘set the time and let the machine do the work.’

As in real life, washing is followed by drying. The resin is cured during the drying process too. This means that the resin then obtains its physical properties. The Cure unit handles this final production stage.

We then have a complete process, which is easy to control, and we are able to produce 3D-printed parts with consistent quality.

Where we go from here…

Research and development are taking place in the field of foodstuffs too. The food of the future will be printed by 3D means. One example of this is the Israeli start-up known as “SavorEat.” It is conducting research into a 3D printing process to enable the production of a complete vegan burger. A burger chain has already been found as a partner for this project. As a result, the wheel has turned full circle back to the beginning of this blog (Computer! Burger with ham and bacon!).

And what is happening at GETT? The Form3 came on to the market in 2019. It prints using the Low Force Stereolithography (LFS) principle. This new technology is able to achieve even better and more precise surfaces and provides quicker results. As we can continue using all the resins and tools from Form2, we have purchased a Form3 to reinforce our “printing team.”

You can discover more about the development process itself in part 2 – from the idea to the finished 3D-printed part. So, stay tuned…

These topics could also interest you...

Capacitive glass operating panel

Industrial panel PC